- Electrical Equipment & Supplies

- Machinery

- Tools & Hardware

- Apparel

- Fashion Accessories

- Gifts & Crafts

- Luggage, Bags & Cases

- Sports & Entertainment

- Business Services

- Energy

- Fabrication Services

- Minerals & Metallurgy

- Electronic Components, Accessories & Telecommunications

- Packaging & Printing

- Vehicles & Accessories

- Beauty & Personal Care

- Food & Beverage

- Home & Garden

- Office & School Supplies

- Timepieces, Jewelry, Eyewear

- Chemicals

- Environment

- Health & Medical

- Rubber & Plastics

- Lights & Lighting

- Security & Protection

- Agriculture

- Consumer Electronics

- Furniture

- Home Appliances

- Shoes & Accessories

- Toys & Hobbies

- Construction & Real Estate

- Fabric & Textile Raw Material

- Home Textiles

- Service Equipment

- Vehicles New & Used

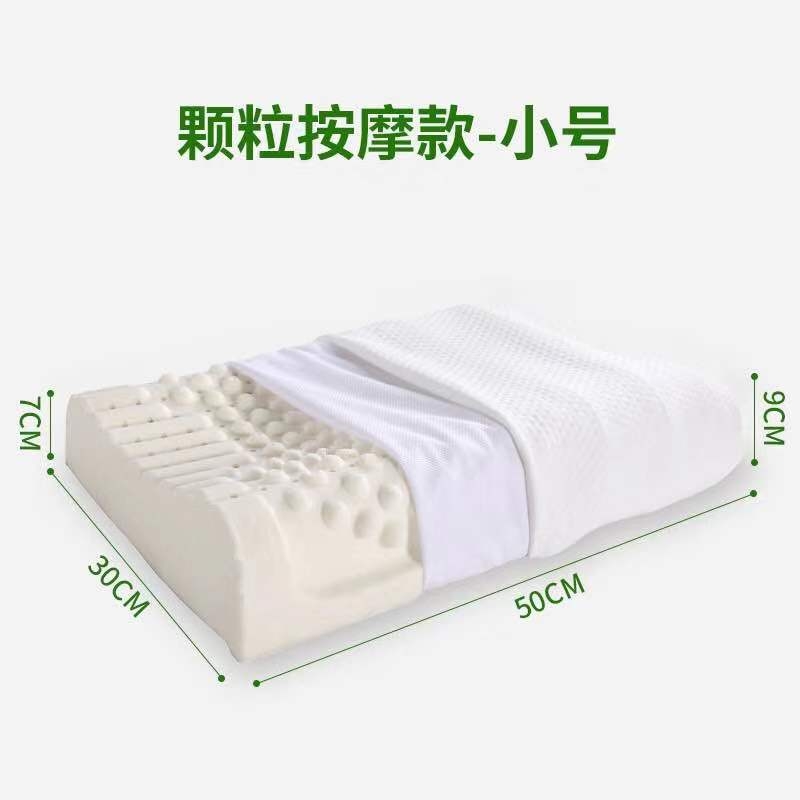

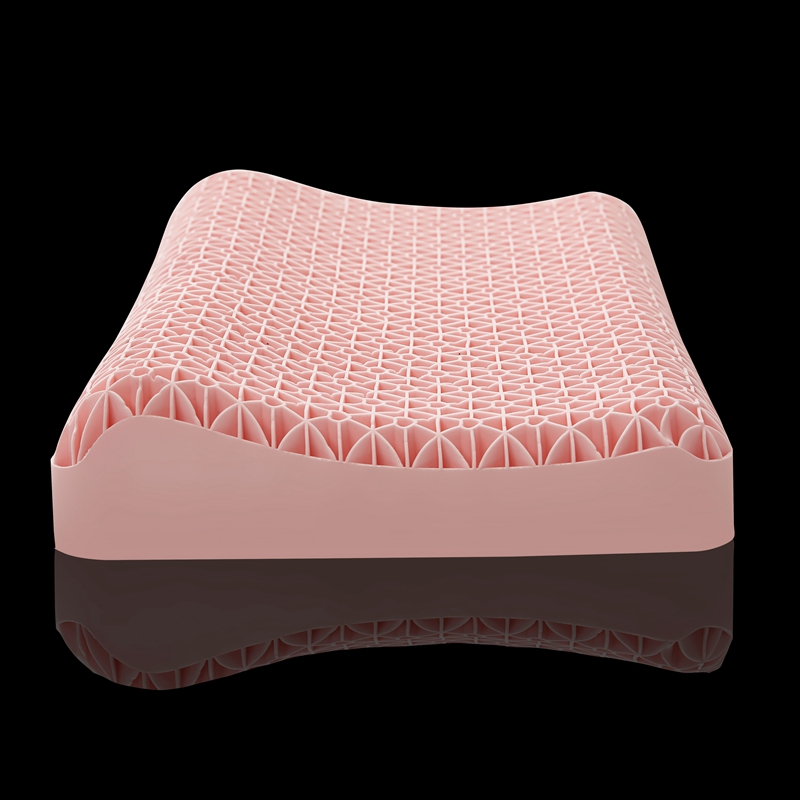

Make a PU pillow

Creating a polyurethane (PU) mold pillow involves several steps. Here's a general overview of the process:

Designing the Mold: The first step is designing the mold for the pillow. This involves determining the shape, size, and structure of the pillow. The mold can be made from various materials such as metal, plastic, or silicone, depending on the complexity of the design and the intended use of the pillow.

Mixing: The polyol and isocyanate chemicals are mixed together in precise proportions to initiate the chemical reaction that forms the polyurethane foam. Additives are also mixed in at this stage to control the properties of the foam, such as density, firmness, and flexibility.

Pouring: Once the foam mixture is ready, it is poured into the mold. The mold is then closed, and the foam begins to expand and fill the mold cavity. The speed at which the foam expands and cures can be controlled by adjusting the formulation of the foam and the ambient temperature and humidity. Curing: After pouring the foam into the mold, it undergoes a curing process to allow it to solidify and take on the desired shape. This typically involves leaving the foam in the mold for a specified amount of time while the chemical reaction continues to progress.

Demolding: Once the foam has cured sufficiently, the mold can be opened, and the newly formed polyurethane mold pillow can be removed. Care must be taken during this step to ensure that the pillow is not damaged as it is removed from the mold.

Finishing: After demolding, the pillow may undergo additional finishing processes, such as trimming any excess foam or adding a cover. These steps help to ensure that the final pillow meets the desired specifications in terms of appearance and functionality.

5 months ago

loading...

pillow block bearing

Shijiazhuang Longshu Mechanical & Electrical Equipment Trading Co., Ltd.

0 views 3 years ago

All Categories

- Electrical Equipment & Supplies

- Machinery

- Tools & Hardware

- Apparel

- Fashion Accessories

- Gifts & Crafts

- Luggage, Bags & Cases

- Sports & Entertainment

- Business Services

- Energy

- Fabrication Services

- Minerals & Metallurgy

- Electronic Components, Accessories & Telecommunications

- Packaging & Printing

- Vehicles & Accessories

- Beauty & Personal Care

- Food & Beverage

- Home & Garden

- Office & School Supplies

- Timepieces, Jewelry, Eyewear

- Chemicals

- Environment

- Health & Medical

- Rubber & Plastics

- Lights & Lighting

- Security & Protection

- Agriculture

- Consumer Electronics

- Furniture

- Home Appliances

- Shoes & Accessories

- Toys & Hobbies

- Construction & Real Estate

- Fabric & Textile Raw Material

- Home Textiles

- Service Equipment

- Vehicles New & Used