- Electrical Equipment & Supplies

- Machinery

- Tools & Hardware

- Apparel

- Fashion Accessories

- Gifts & Crafts

- Luggage, Bags & Cases

- Sports & Entertainment

- Business Services

- Energy

- Fabrication Services

- Minerals & Metallurgy

- Electronic Components, Accessories & Telecommunications

- Packaging & Printing

- Vehicles & Accessories

- Beauty & Personal Care

- Food & Beverage

- Home & Garden

- Office & School Supplies

- Timepieces, Jewelry, Eyewear

- Chemicals

- Environment

- Health & Medical

- Rubber & Plastics

- Lights & Lighting

- Security & Protection

- Agriculture

- Consumer Electronics

- Furniture

- Home Appliances

- Shoes & Accessories

- Toys & Hobbies

- Construction & Real Estate

- Fabric & Textile Raw Material

- Home Textiles

- Service Equipment

- Vehicles New & Used

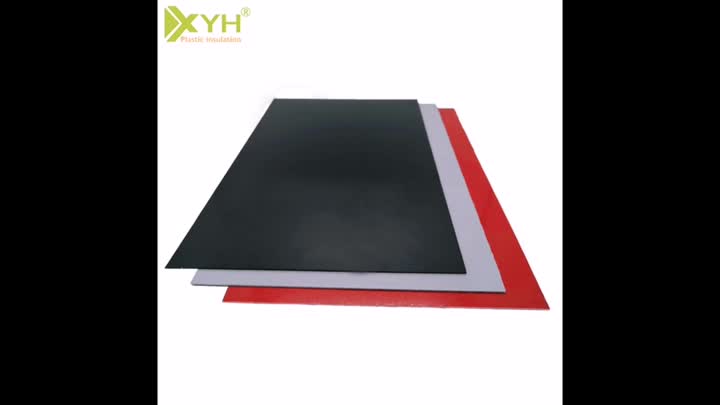

extruding abs plastic sheet

Here are the general steps involved in the process:

1. Preparing the ABS Plastic: ABS plastic is typically supplied in pellet form. These pellets are usually dried before extrusion to remove any moisture content that may affect the quality of the final product.

2. Feeding the Extruder: The dried ABS plastic pellets are then fed into the hopper of the extrusion machine. The hopper feeds the pellets into a heated barrel.

3. Melting and Mixing: Inside the barrel, the ABS plastic pellets are heated to a molten state. The barrel is equipped with a screw mechanism that rotates and pushes the molten plastic forward. The rotating screw also helps in mixing any additives or colorants that may be added to the plastic.

4. Extrusion Die: At the end of the barrel, the molten ABS plastic is forced through a specially designed die. The die determines the shape and thickness of the extruded sheet. It can be customized to produce sheets of different sizes and profiles.

5. Cooling and Sizing: As the molten ABS plastic exits the die, it is immediately cooled using a cooling system, such as water or air. This rapid cooling solidifies the plastic into a sheet form. The sheet is then passed through sizing rollers or a calibration table to ensure it has the desired thickness and dimensions.

6. Cutting and Winding: Once the ABS plastic sheet has been cooled and sized, it is cut into the desired length and wound onto a roll or cut into sheets of specific dimensions.

1 year ago

loading...

Plastic Acrylic ABS Sheet Toy Molding Thermoforming Vacuum Machine Equipment Price — Manufacturers1

Weifang Yunneng CNC Equipments Co., Ltd.

0 views 1 week ago

All Categories

- Electrical Equipment & Supplies

- Machinery

- Tools & Hardware

- Apparel

- Fashion Accessories

- Gifts & Crafts

- Luggage, Bags & Cases

- Sports & Entertainment

- Business Services

- Energy

- Fabrication Services

- Minerals & Metallurgy

- Electronic Components, Accessories & Telecommunications

- Packaging & Printing

- Vehicles & Accessories

- Beauty & Personal Care

- Food & Beverage

- Home & Garden

- Office & School Supplies

- Timepieces, Jewelry, Eyewear

- Chemicals

- Environment

- Health & Medical

- Rubber & Plastics

- Lights & Lighting

- Security & Protection

- Agriculture

- Consumer Electronics

- Furniture

- Home Appliances

- Shoes & Accessories

- Toys & Hobbies

- Construction & Real Estate

- Fabric & Textile Raw Material

- Home Textiles

- Service Equipment

- Vehicles New & Used