- Electrical Equipment & Supplies

- Machinery

- Tools & Hardware

- Apparel

- Fashion Accessories

- Gifts & Crafts

- Luggage, Bags & Cases

- Sports & Entertainment

- Business Services

- Energy

- Fabrication Services

- Minerals & Metallurgy

- Electronic Components, Accessories & Telecommunications

- Packaging & Printing

- Vehicles & Accessories

- Beauty & Personal Care

- Food & Beverage

- Home & Garden

- Office & School Supplies

- Timepieces, Jewelry, Eyewear

- Chemicals

- Environment

- Health & Medical

- Rubber & Plastics

- Lights & Lighting

- Security & Protection

- Agriculture

- Consumer Electronics

- Furniture

- Home Appliances

- Shoes & Accessories

- Toys & Hobbies

- Construction & Real Estate

- Fabric & Textile Raw Material

- Home Textiles

- Service Equipment

- Vehicles New & Used

Tungsten carbide parts ready for sintering

Do you know tungsten carbide sintering process?

Sintering process of cemented carbide

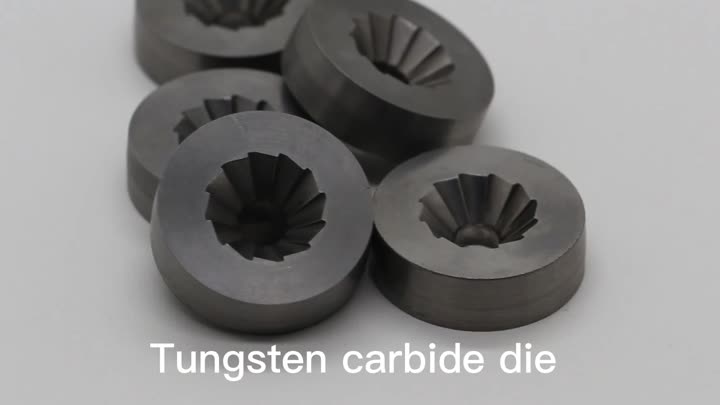

Cemented carbide is composed of various carbides and iron group elements, such as WC Co WC TiC TaC NbC Co or TiC Mo. The typical feature of these materials is that they can achieve almost 100% theoretical density through liquid-phase sintering. After sintering, the low residual porosity is the successful application of cemented carbide in high-stress applications such as orifice rings and bottom sleeves,Carbide Blades And Insert oil mining bits or Carbide Dies.

The key of working conditions. In addition, the sintering process must be carefully controlled to obtain the desired microstructure and chemical composition.

In many applications, cemented carbides are used as sintered. The sintered alloy surface often suffers from harsh friction and stress conditions. In most metal cutting applications, the tool will be scrapped as long as the wear depth of the tool head surface exceeds 0.2~0.4 mm. Therefore, it is very important to improve the surface performance of cemented carbide.

Two basic methods for sintering CARBIDE WEAR PARTS:

One is that hydrogen sintering controls the composition of parts through phase reaction kinetics in hydrogen and under normal pressure; the other is that vacuum sintering uses vacuum environment or reduces ambient gas pressure to control the composition of cemented carbide by slowing down reaction kinetics. Vacuum sintering has more extensive industrial applications. Sometimes, sintering hot isostatic pressing (HIP) and hot isostatic pressing (HIP) are also used. These technologies have an important impact on the production of cemented carbide.

Hydrogen sintering: hydrogen is a reducing atmosphere, but when hydrogen reacts with the sintering furnace wall or bearing device, it will change other components to provide appropriate carbonization potential to maintain the thermodynamic balance with cemented carbide. In the traditional sintering of cemented carbide, the carbon content of carbide in the mixture should be adjusted to the theoretical value, and this value should be kept unchanged throughout the hydrogen sintering process. For example, when sintering 94WC-6C cemented carbide, the carbon content is 5.70~5.80% (mass fraction) when entering the furnace, and it should be maintained at 5.76+0.4% when exiting the furnace

The atmosphere control capability of the hydrogen sintering process is sufficient for tungsten cobalt cemented carbides. However, for the alloy containing titanium carbide, tantalum carbide or niobium carbide used for steel cutting tools, the oxidation potential of the atmosphere is too high, resulting in changes in the composition of the alloy. Vacuum sintering is usually used to reduce these. The content of alloy oxides. Hydrogen sintering is generally completed by mechanical rowing through continuous sintering, A separate pre sintering furnace can be used to remove lubricant to prevent high sintering process after volatile pollution. Pre sintering can also increase the embryo strength to enable rough cutting, such as turning and drilling. The pre sintering temperature is 500~800 ℃, which mainly depends on whether the lubricant is completely removed and the required embryo strength.

1 year ago

loading...

tungsten carbide sheet for cutting tools

Zhuzhou Kerui Cemented Carbide Co., Ltd.

0 views 1 year ago

tungsten carbide gauge protection tip insert

Zhuzhou Kerui Cemented Carbide Co., Ltd.

0 views 2 years ago

All Categories

- Electrical Equipment & Supplies

- Machinery

- Tools & Hardware

- Apparel

- Fashion Accessories

- Gifts & Crafts

- Luggage, Bags & Cases

- Sports & Entertainment

- Business Services

- Energy

- Fabrication Services

- Minerals & Metallurgy

- Electronic Components, Accessories & Telecommunications

- Packaging & Printing

- Vehicles & Accessories

- Beauty & Personal Care

- Food & Beverage

- Home & Garden

- Office & School Supplies

- Timepieces, Jewelry, Eyewear

- Chemicals

- Environment

- Health & Medical

- Rubber & Plastics

- Lights & Lighting

- Security & Protection

- Agriculture

- Consumer Electronics

- Furniture

- Home Appliances

- Shoes & Accessories

- Toys & Hobbies

- Construction & Real Estate

- Fabric & Textile Raw Material

- Home Textiles

- Service Equipment

- Vehicles New & Used